Industrial machinery division Steelmaking equipment

We will provide the best service with advanced technology and top-quality products.

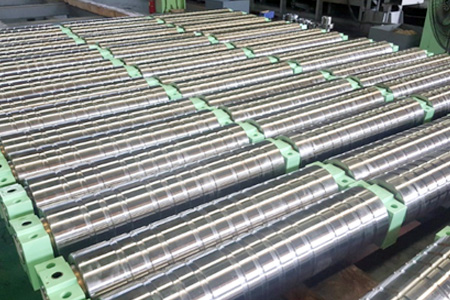

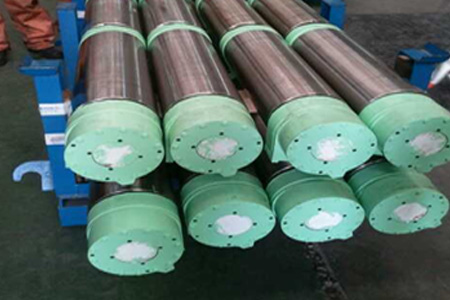

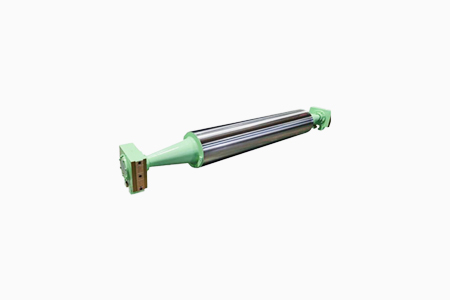

Continuous casting

The ROLL used for continuous casting equipment is used for the purpose of producing SLAB, BLOOM, and BEAM BLANK for STANDGUIDE production lines. We focus on producing ROLL suitable for high temperature, corrosion resistance, wear resistance, and crack resistance using HARD FACING (SUBMERGED method) process. We also have our own assembly and disassembly equipment.

Hot Rolled Steel, Steel Plate, Cold Rolled Steel

The rollers and auxiliary equipment for hot rolling, plate, and cold rolling facilities include rollers for hot rolling, which heats and rolls slabs into semi-finished steel products, table rollers for transporting rolled steel plates, and rollers for pre and post-processing required for producing cold-rolled steel plates, including input and output equipment and accessories (including roll frames), are produced based on our own technological capabilities. We assemble and conduct test runs to deliver the highest quality products to our customers.

Hot Rolled Steel

Steel Plate

Cold Rolled Steel

ø200~ø400 Table rolls

Back up rolls

(ø500x1,200L/2,500L)

(ø500x1,200L/2,500L)

High abrasion Resistant

pinch rolls (ø474x1,200L)

pinch rolls (ø474x1,200L)

High precision rolls for Warm mill

(ø300~ø650mm)

(ø300~ø650mm)

Work rolls for Cold Mill

(ø180x1,500L)

(ø180x1,500L)

Work rolls for CRM

(ø245x2,500L)

(ø245x2,500L)

Cold Mill Tension Bridle roll

(ø1200x2000L)

(ø1200x2000L)

Cold Mill Leveller roll

( Ø 300 * 5,800L )

( Ø 300 * 5,800L )

DOWN COILER UNIT ROLL

( Ø380 x 2,080L)

( Ø380 x 2,080L)

LOOPER ROLL

( Ø185 x 2,100 )

( Ø185 x 2,100 )

FSB TOP/BOTTOM ROLL

( Ø510 / Ø350 x 2,580 )

( Ø510 / Ø350 x 2,580 )

Other rolls