Process Industrial Machinery Division

JINSUNG C&I is always striving to become a global top-tier company.

Production process

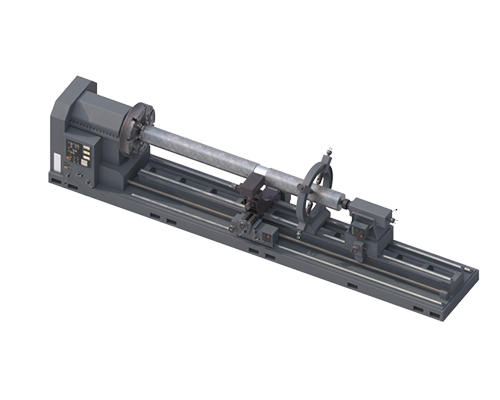

1. Rough Machining

Surface processing prior to surface modification through dedicated equipment.

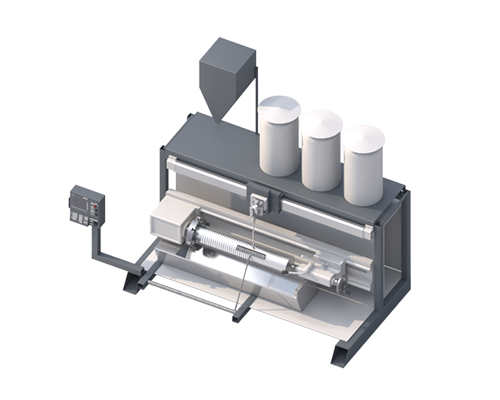

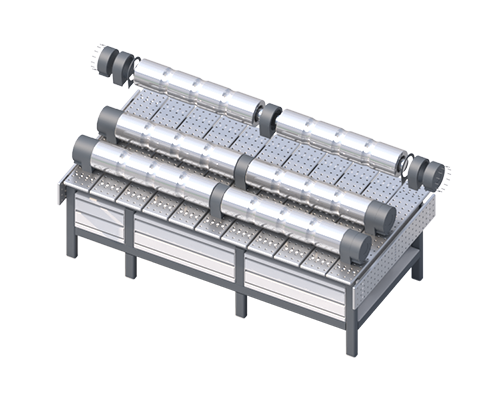

2. Hard Facing

To enhance the wear resistance and corrosion resistance of metal surfaces, a surface conditioning process is performed using the SAW (Submerged Arc Welding) method to improve mechanical and chemical properties.

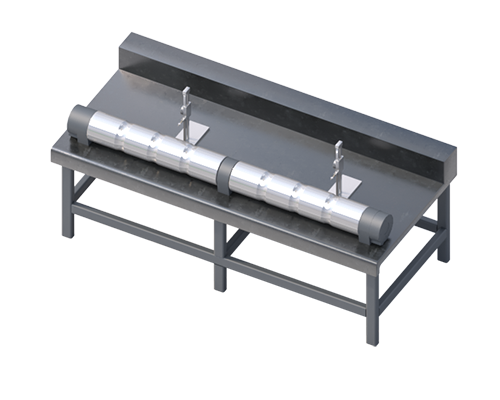

3. Induction Hardening

The method of improving the mechanical properties of the surface layer by applying induced current to the metal surface.

4. Laser Cladding

The process of melting high-quality metal powder with excellent wear resistance, corrosion resistance, and heat resistance using high-power laser as the heat source, and bonding it to the substrate through metallurgical bonding.

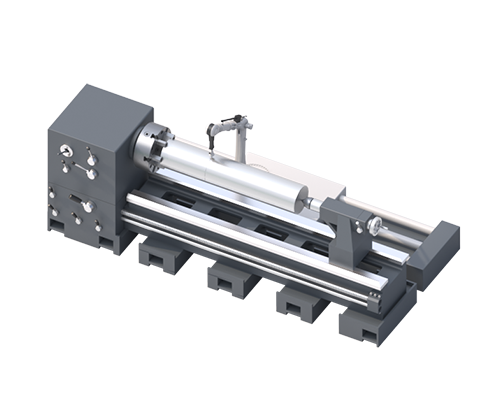

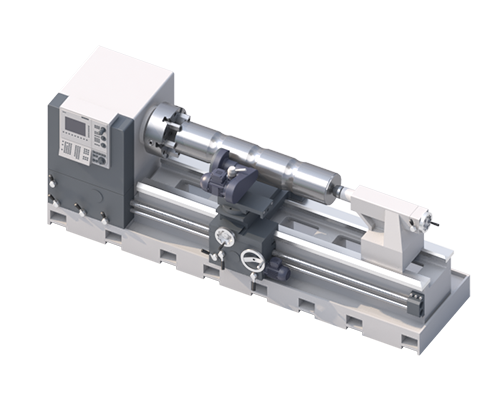

5. Final Machining

Final precision machining of products using dedicated equipment.

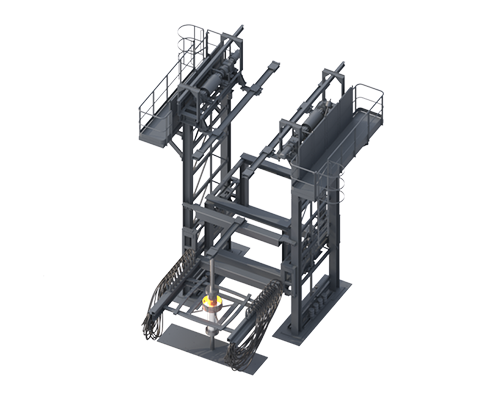

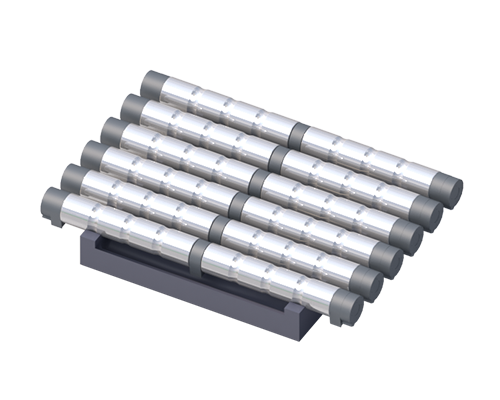

6. Assembly

Assembling parts according to customer requirements.

7. Final Inspection

Conducting final dimensional and visual inspections according to quality standards.

8. Shipping

Packing finished products in accordance with packaging specifications and ensuring safe transportation to customers.