Research and Development

JINSUNG C&I leads the industry through continuous research and development.

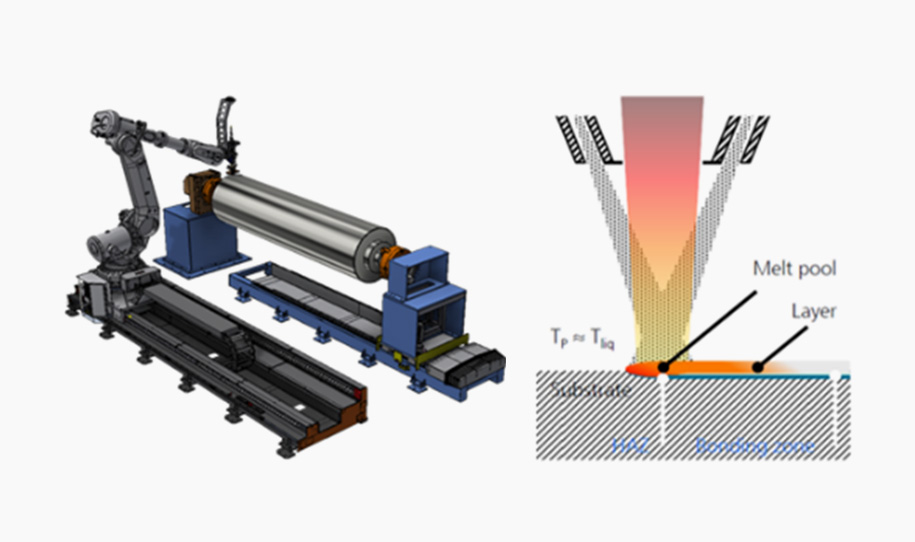

L/C (Laser Cladding)

The technology involves melting metal powder using a domestically pioneered/largest 20kW high-power diode laser as the heat source. This ensures a coating layer by bonding the substrate and the metal through metallurgical means, offering excellent wear resistance, corrosion resistance, and heat resistance.

The technology minimizes the thermal distortion and excessive dilution issues of conventional SAW (Submerged Arc Welding) hardfacing. It also overcomes the spalling problem of thermal spray and fusing, as well as the limitation in controlling the thickness of the coating layer.

Comparison of manufacturing methods

| Distinction | L/C | SAW | Thermal Spray | |

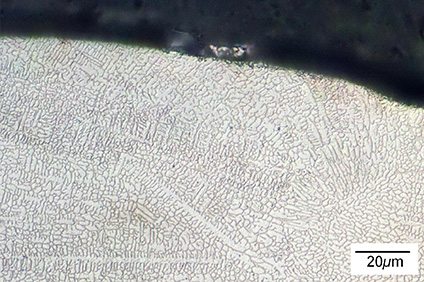

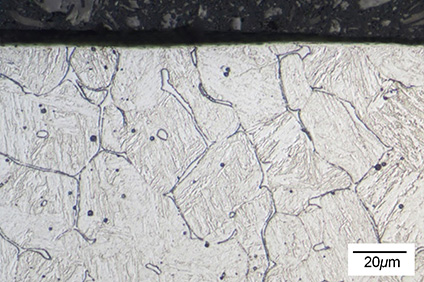

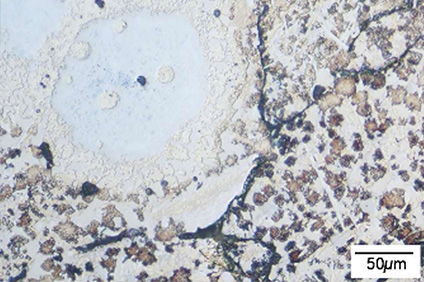

|---|---|---|---|---|

| 01 | Heat Source | Laser | Arc | Flame |

| 02 | Dilution rate | 3 ~ 10% | 30 ~ 60% | 0% |

| 03 | Bonding strength(Mpa) | ≤ 600 | ← | ≤ 250 |

| 04 | Bonding type | Metal bonding | ← | Diffusion bonding |

| 05 | Layer deposition height | 0.3 ~ 3.0mm | 2.0 ~ 4.0mm (Inability to achieve thin layer deposition) | 0.1~1.5mm (Inability to achieve thick layer deposition) |

| 06 | Thermal deformation | Good | Bad | Good |

| 07 | Method Characteristics | Highly functional, debris-free, stacked tissue formation resulting from rapid cooling rates (mechanically relatively ↑) | One of the largest structural repair methods is deformation due to damage during repair work. | High-temperature wear-resistant, corrosion-resistant, inverted Ni-based self-soluble coating is possible, but there is a high possibility of sudden spalling phenomenon due to the ball and force due to the diffusion bonding method. |

| 08 | Method and Organizational Photos |

|

||

External Activities

2023.10 Spring Conference of the Metallurgical Materials Society

Oral Presentation: Study on the Enhancement of Durability in Continuous Casting Guide Rolls Manufactured by HPDDL + SAW Composite Layer Manufacturing Method

Poster Presentation: Study on Post-Usage Phenomena of Continuous Casting Guide Rolls Manufactured by HPDDL + SAW Composite Layer Manufacturing Method

2023.04 Spring Academic Conference of the Metallurgical Materials Society

Comparative Analysis of the HPDDL and SAW Cladding by Fe-based alloy

of Continuous Caster Rolls

2022. KIMS TECHFAIR booth presentation

KIMS Techfair

2019. Hyundai Steel TECH SHOW

Laser Cladding

Patent accomplishments

Patent application

Manufacturing method of guide rolls for continuous casting equipment

10-2023-0027293

2023.02.28

Utility patent

Support rolls for continuous casting machines

1018878730000

2018.08.07

Design patent

Support rolls for continuous casting machines

3009369140000

2017.12.19

Utility patent

Heat treatment device for ring flanges using induction heating coils

1011939610000

2012.10.17

Utility patent

Multiple induction heating device for boilers

1011442420000

2012.05.02

Utility patent

Multiple induction heating device for boilers

1010801080000

2011.10.31

Utility patent

Automatic drilling machine for pin hole machining

10089226700000

2009.04.01

Utility patent

Continuous heat treatment method and apparatus for sheet metal using induction heating

1006945590000

2007.03.07